JULI® Accessories & Fittings

JULI® Accessories & Fittings

Product Information

JULI® Accessories & Fittings can be made with PVC flexible fabric, polyester fiber as the base fabric, and coated with PVC membrane on both sides. Polyester fiber can be chosen for different user requirements and environments. The PVC membrane is fire resistant with DIN4102 B1, NFPA701, EN13501, MSHA, DIN75200, and antistatic properties, all are accompanied by an SGS test result.

Product Parameter

| JULI® Accessories and Fittings Technical Specification | ||

| Item | Unit | Value |

| Diameter | mm | 300-3000 |

| Section length | m | 5, 10, 20, 30, 50, 100, 200, 300 |

| Color | - | Yellow, Orange, Black |

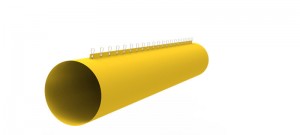

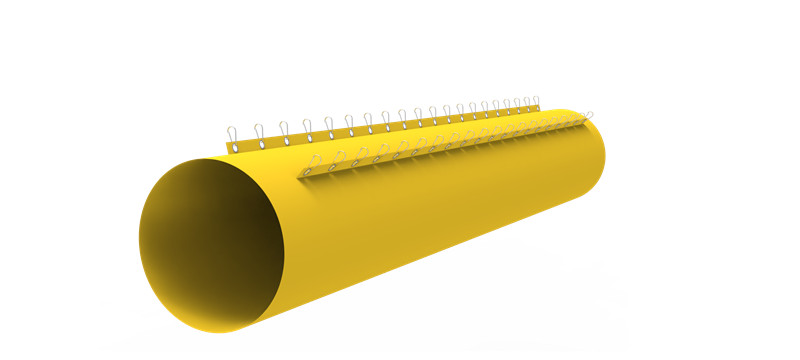

| Suspension | - | Diameter<1800mm, single suspension fin/patch |

| Diameter≥1800mm, double suspension fins/patches | ||

| Sealing face sleeve | mm | 150-400 |

| Grommet spacing | mm | 750 |

| Coupling | - | Zipper/Velcro/Steel ring/Eyelet |

| Fire resistance | - | DIN4102 B1/EN13501/NFPA701/MSHA/DIN75200 |

| Antistatic | Ω | ≤3 x 108 |

| Packing | - | Pallet |

| The above values are average for reference, allowing 10% tolerance. Customization is acceptable for all given values. | ||

Product Feature

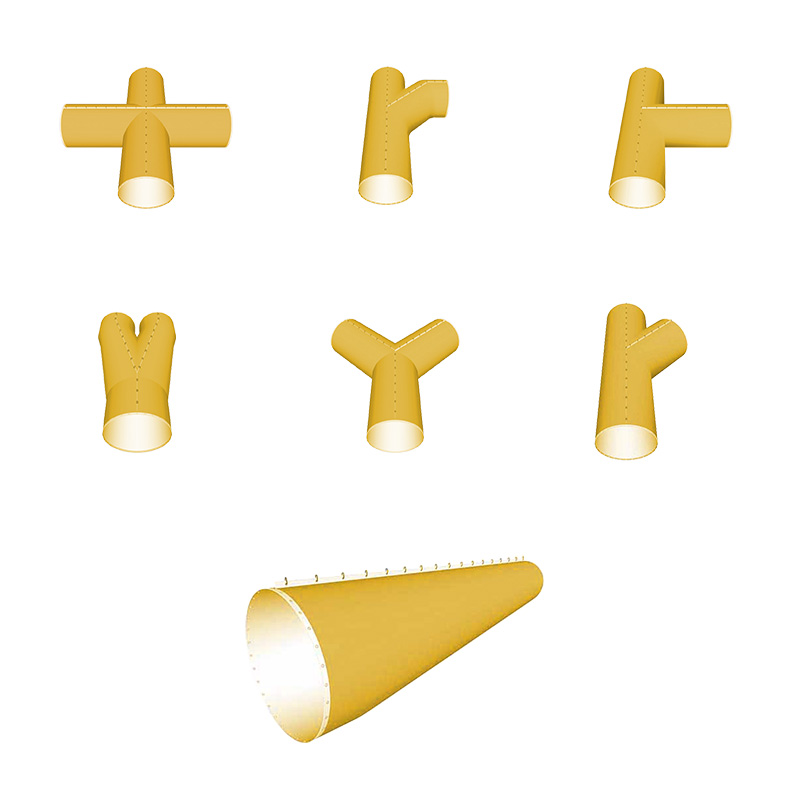

◈ Used for turning, reducing, switching, and connecting the main and branch tunnels.

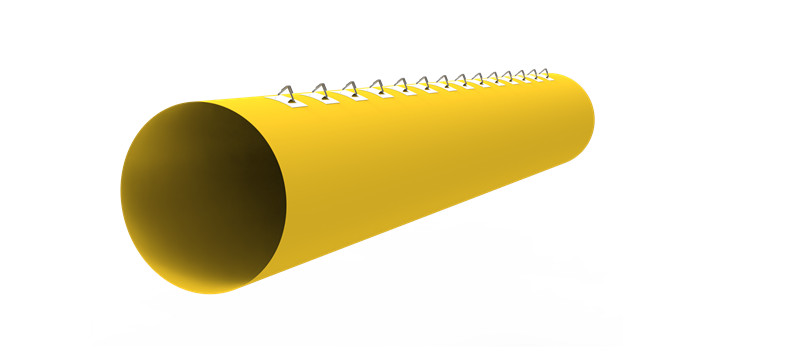

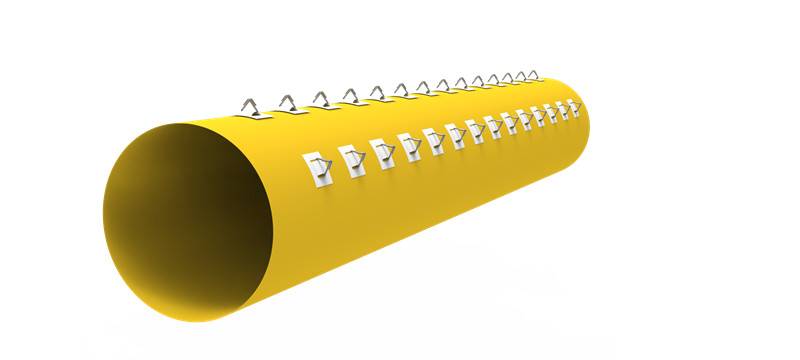

◈ All fittings are available in both layflat and spiral, as well as oval.

◈ Many different fittings in various diameters, configurations, and lengths.

◈ The great flexibility of fittings adapts perfectly to your conditions.

◈ Processing with supplied drawings or samples is acceptable.

◈ Polyester woven or knit fabric with a PVC coating on both sides.

◈ The flame resistance meets DIN4102 B1/EN13501/NFPA701/MSHA/DIN75200 standards.

◈ Diameters range from 300mm to 3000mm. Customization is acceptable for other dimensions.

Product Advantage

Over 15 years of experience in the production of PVC flexible air ventilation ducts and fabric, a strong scientific research team, over ten engineering and technical staff with professional college degrees, over 30 high-speed rapier looms, three composite production lines with an annual output of more than 10,000 tons of calendered membranes, and three automatic ducting welding production lines with an annual output of more than 15 million square meters of fabric, provide long-term support and services for fans' company and large projects at home and abroad.

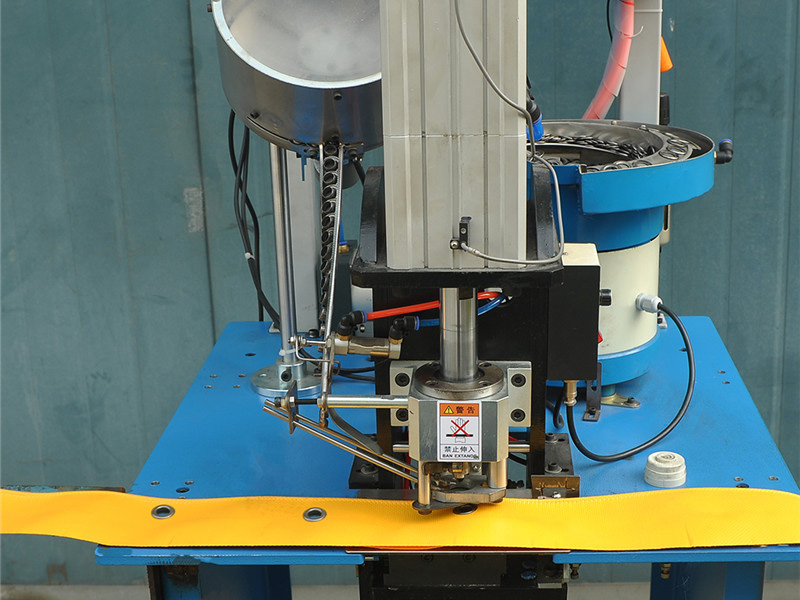

Automatic suspension fin/patch, fabric joining, duct body welding, the welding seam is even and stable, decreasing the influence of human factors on welding stability. The welding efficiency is 2-3 times that of a traditional welding machine, and the lead time is reduced.

The eyelets are automatically buckled by the automatic machine to prevent them from falling off.

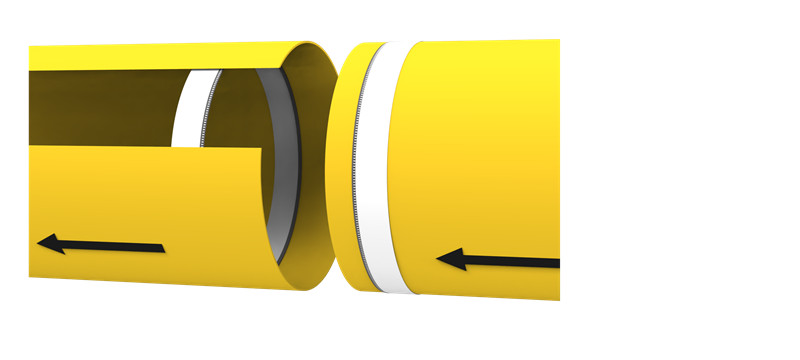

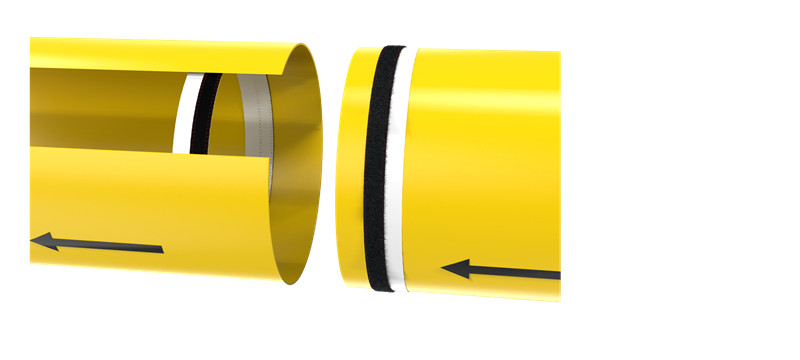

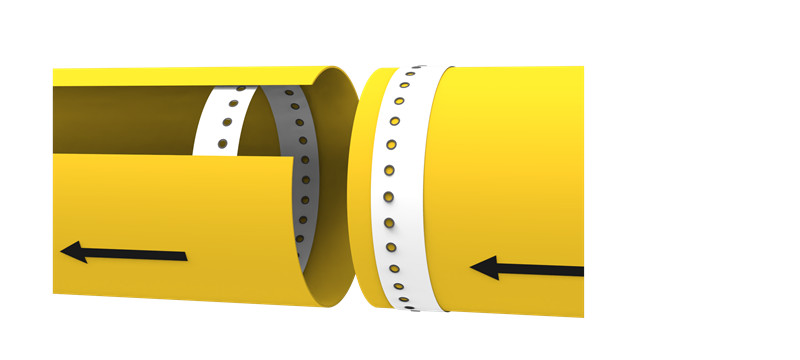

The oval ventilation duct's basic connections are zipper and Velcro. The extra fabric on which the zipper/Velcro is sewed is welded to the flexible duct body to ensure that there are no sewing needle eyes throughout the ducting, reducing air leakage. The long sealing face sleeve covers the zipper or Velcro, reducing the risk of bursting.

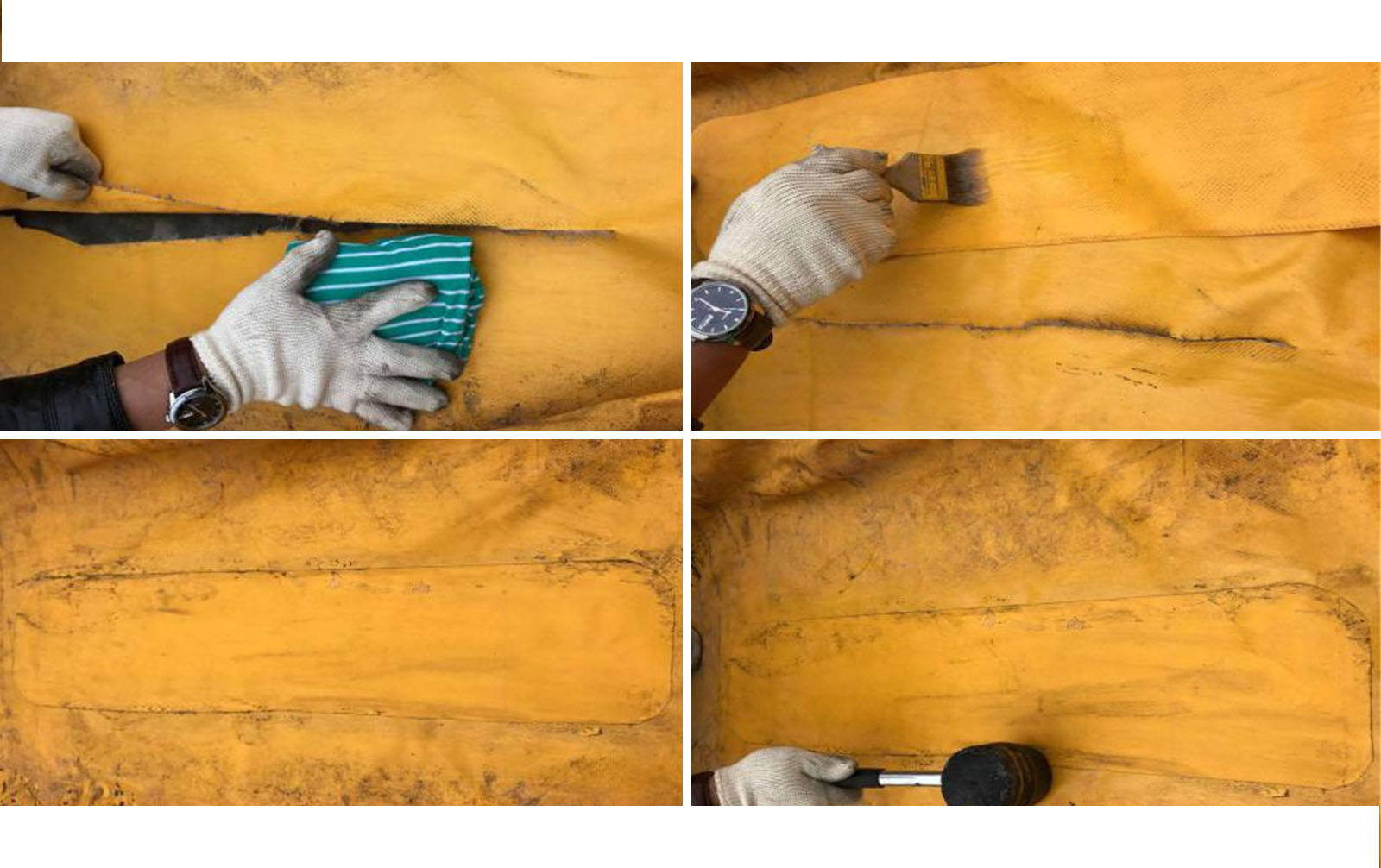

Flexible repair methods: glue, zipper repair band, Velcro repair band, and portable hot air gun.

Several automatic ducting welding production lines with a monthly output of 20,000 flexible ventilation tubes guarantee an assured batch order lead time.

Pallet packing will be designed according to the order quantity and the container size, trying to save transportation costs.

As one of the Chinese standard drafters for flexible ventilation ducting, Foresight is dedicated to the research, design, and development of underground ventilation safety, always taking responsibility for improving the quality of the flexible ventilation tube, extending the service life, reducing the frequency of replacement, and lowering the energy consumption of ventilation equipment, as well as continuously optimizing the unit tunneling cost to improve the product's overall cost performance.