Complete industrial chain

Base fabric, calendering, lamination/semi-coated, surface treatment, and finished product manufacturing are the five industries of Foresight. It covers the entire composite material production process and guarantees the customer's customized design. Customer demand exploration, product research and development, product production, and technical services to provide customers with system solutions are all part of Foresight's business.

Base fabric workshop:

◈ Make the base fabric.

◈ 2 sets of intelligent slitting warping equipment.

◈ 4 sets of double-twisting equipment

◈ 32 rapier loom sets

◈ 1,500,000 square meters of monthly production capacity

Calendaring workshop:

◈ Make PVC film

◈ SY-4 plastic calender machine

◈ Design and produce as the special needs of customers

◈ 10,000 tons of output per year

Compound workshop:

◈ Combining the base fabric and PVC film

◈ 2 sets of lamination machines

◈ 1 semi-coated machine set

◈ 1 antistatic surface treatment machine set

◈ Monthly production capacity of more than 2,000,000 square meters.

Finished product workshop:

◈ Cover an area of 4,000 square meters

◈ 4 sets of self-developed automatic welding machines for layflat ventilation ducts

◈ 1 set of automatic fabric splicing machines for ventilation ducts with large diameters

◈ 3 sets of automatic welding machines for spiral ventilation ducts

◈ 33-meter-long movable high-frequency machine

◈ Intergrated professional team with over 20 years of experience

◈ Annual output is 5-10 million meters

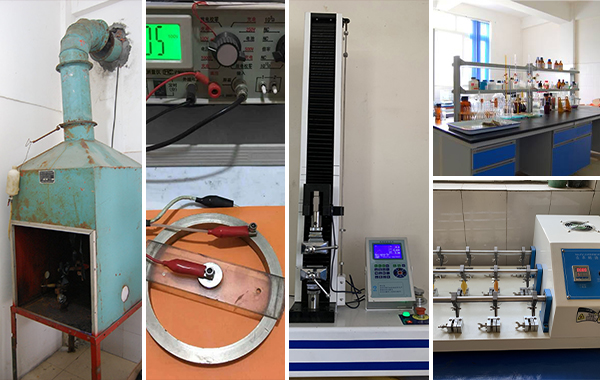

Quality Control Laboratory:

◈ Advanced infrastructure and production, processing, and testing equipment, as well as a manufacturing environment and an innate foundation to ensure product quality

◈ A systematic training and assessment system to ensure the continuous improvement of staff skills and quality awareness

◈ Equipment management system that is refined and predictable in order to continuously reduce the rate of equipment failure

◈ Systematized management system of suppliers and raw materials to ensure quality control at the source

◈ Application of advanced tools and methods to ensure continuous improvement of all internal links;

◈ The K3 system has been established. From the purchase of raw materials to the production of semi-finished products and finished products, the factory has a complete set of data links. All products have barcodes, and each product has traceability