Super Purchasing for Mining Material - JULI® Antistatic Ventilation Duct – Foresight

Super Purchasing for Mining Material - JULI® Antistatic Ventilation Duct – Foresight

Super Purchasing for Mining Material - JULI® Antistatic Ventilation Duct – Foresight Detail:

Product Informations

JULI® antistatic ventilation duct is primarily designed for high concentration gas in the underground, such as coal mines and tunnels. Antistatic duct fabric is treated with a water-based surface material that is environmentally friendly, emits no VOC during processing and use, is safe for workers, and stabilizes the antistatic value at 3×106Ω.

The fire resistance of the JULI® antistatic ventilation duct is DIN4102 B1, NFPA701, EN13501, DIN75200, and all fire resistance is accompanied by an SGS test result. When a fire is present, a high flame retardant can help to limit the hazardous and harmful gases that can injure the human body.

suspension system

Single suspension fin

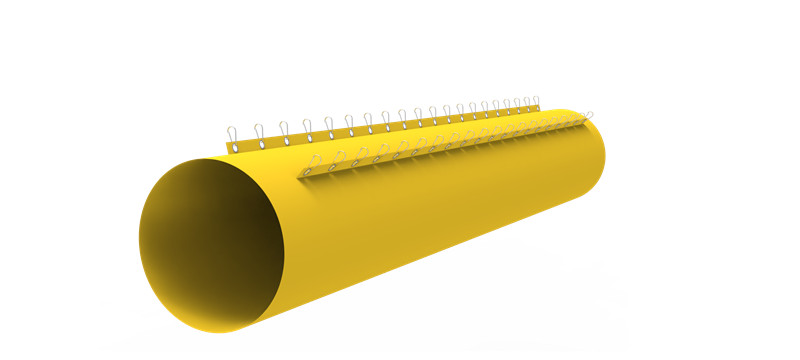

Dpuble suspension fins

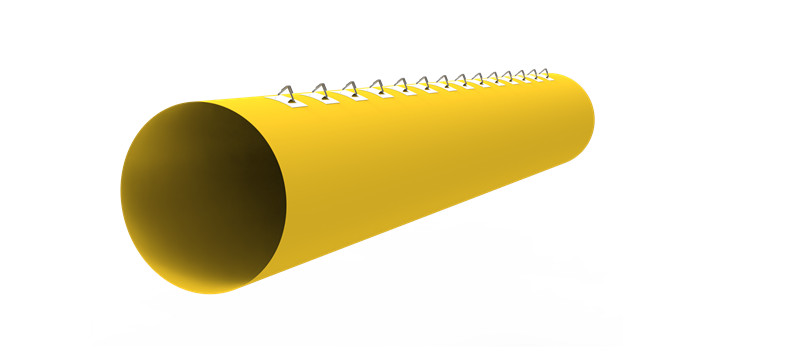

Single suspension patch

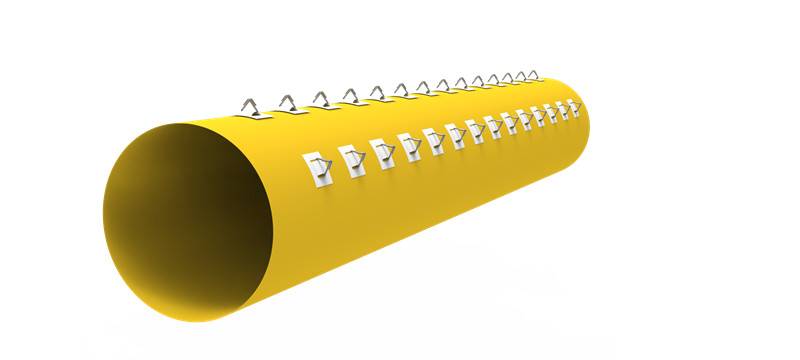

Double suspension patches

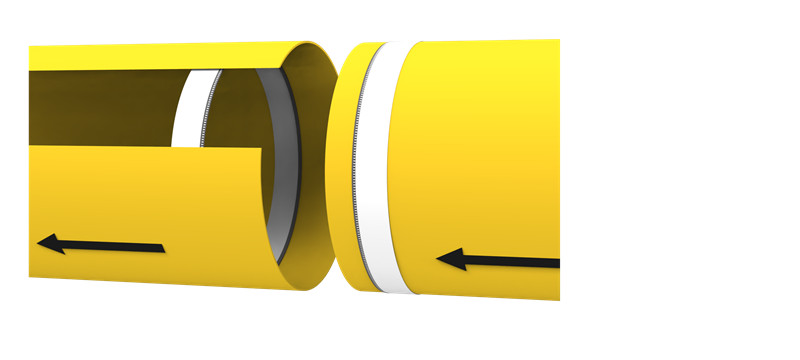

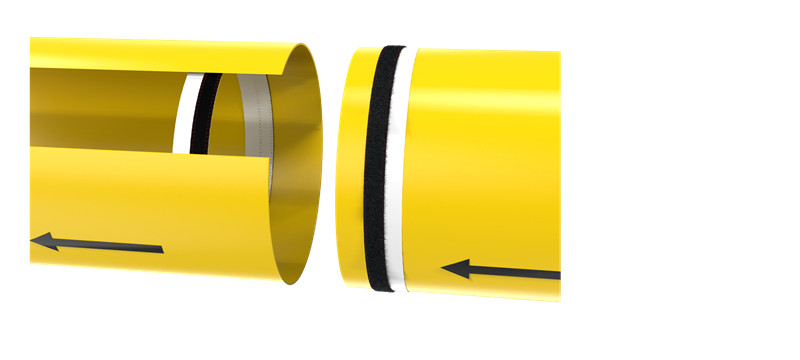

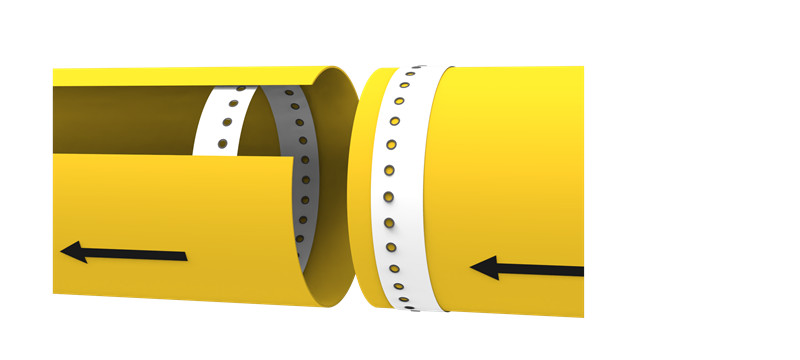

Coupling system

Zipper Coupling

Velcro Coupling

Eyelet Coupling

End ring Coupling

Product Parameters

| JULI® Antistatic Ventilation Ducting Technical Specification | ||

| Item | Unit | Value |

| Diameter | mm | 300-3000 |

| Section length | m | 5, 10, 20, 30, 50, 100, 200, 300 |

| Color | - | Yellow, Orange, Black |

| Suspension | - | Diameter<1800mm, single suspension fin/patch |

| Diameter≥1800mm, double suspension fins/patches | ||

| Sealing face sleeve | mm | 150-250 |

| Grommet spacing | mm | 750 |

| Coupling | - | Zipper/Velcro/Steel ring/Eyelet |

| Fire resistance | - | DIN4102 B1/EN13501/NFPA701/DIN75200 |

| Antistatic | Ω | ≤3 x 108 |

| Packing | - | Pallet |

| The above values are average for reference, allowing 10% tolerance. Customization is acceptable for all given values. | ||

Product Feature

◈ Used for tunnels and mining with high concentrations of toxic gas.

◈ All ducting and fittings are available in both layflat and spiral as well as oval.

◈ The standard color is black, but other colors can be customized.

◈ Airtight seams and grommets are soldered, resulting in negligible friction loss.

◈ Polyester woven or knit fabric with a PVC coating on both sides.

◈ The flame resistance meets DIN4102 B1/EN13501/NFPA701/DIN75200 standards.

◈ Customization is available for diameters ranging from 200 mm to 3000 mm.

◈ Section lengths can reach 200m, 300m, or even longer when designed specifically for TBM, and lifetimes can range from 5 to 10 years.

Product Advantages

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Super Purchasing for Mining Material - JULI® Antistatic Ventilation Duct – Foresight , The product will supply to all over the world, such as: Eindhoven, Tunisia, Cyprus, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,