Hot New Products Underground Ventilation Pipe - JULI® Explosion-Proof Water Barrier Bag – Foresight

Hot New Products Underground Ventilation Pipe - JULI® Explosion-Proof Water Barrier Bag – Foresight

Hot New Products Underground Ventilation Pipe - JULI® Explosion-Proof Water Barrier Bag – Foresight Detail:

Product Informations

JULI® explosion-proof water barrier bag is used to isolate the spread of gas (combustible gas) and coal dust explosions. To prevent coal dust explosions and control the expansion of coal dust explosion disasters, ensure that coal and semi-coal rocks are in each mining area, at the upper and lower exits of the tunneling surface, and also transport roads, etc. to ensure sufficient water volume, To prevent the spread of gas and coal dust explosion accidents, the propagation of coal dust explosion shock waves is blocked.

Product Parameters

| Item | Unit | SDCJ5591 | Excutive Standard | ||||

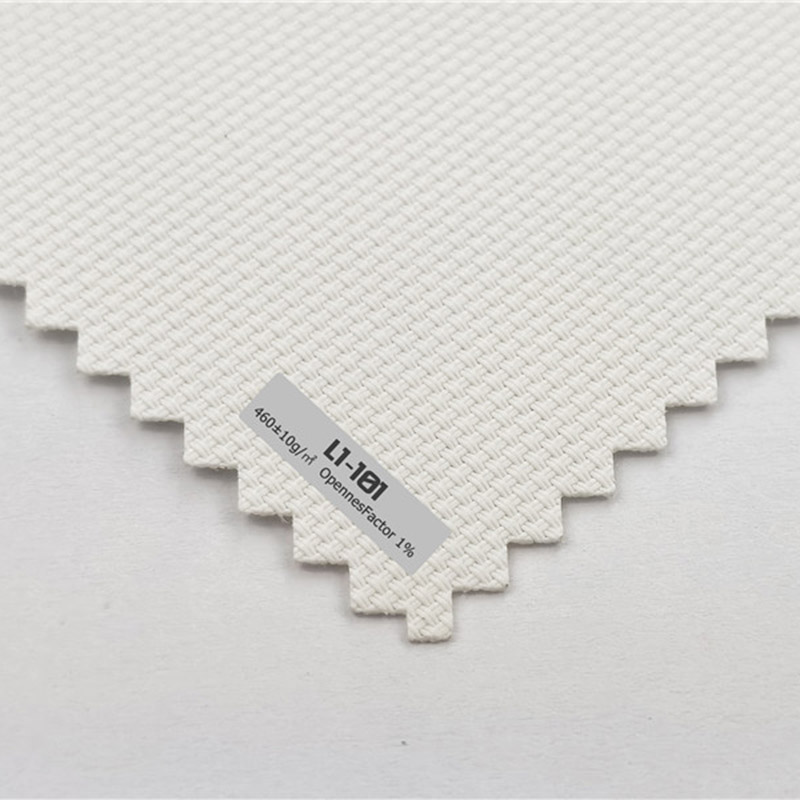

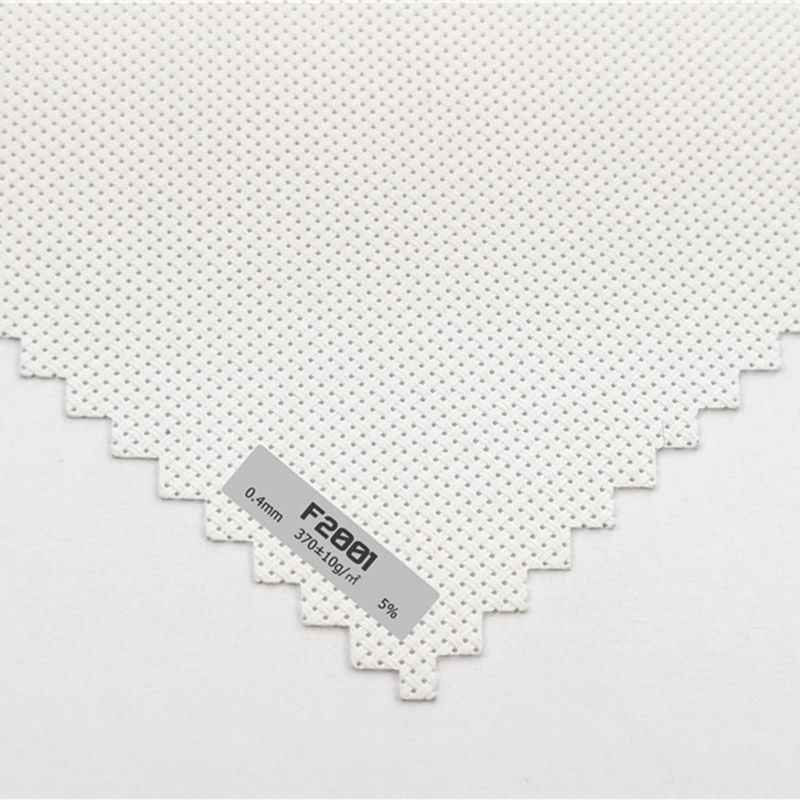

| Base fabric | - | High strength low shrink polyester fiber | DIN EN 60001 | ||||

| Titer of yarn | D | 540*500 | DIN EN ISO 2060 | ||||

| Color | - | Orange | - | ||||

| Weave Style | - | Knitted fabric | DIN ISO 934 | ||||

| Total weight | g/m2 | 420 | DIN EN ISO 2286-2 | ||||

| Tensile Strength (Warp/Weft) |

N/5cm | 800/600 | DIN 53354 | ||||

| Tear strength (Warp/Weft) |

N | 120/110 | DIN53363 | ||||

| Adhesion strength | N/5cm | 60 | DIN53357 | ||||

| Threshold Temperature | ℃ | -25~60 | DIN EN 1876-2 | ||||

| Fire resistance | - | DIN4102 B1/EN13501/NFPA701/DIN75200 | DIN4102 B1/EN13501/NFPA701/DIN75200 | ||||

| Oxygen Index | % | 30 | BB/T0037-2012 | ||||

| Antistatic | Ω | ≤3 x 108 | DIN54345 | ||||

| Item | Unit | Type | |||||

| GD30 | GD40 | GD60 | GD80 | ||||

| Standard Size | L | 30 | 40 | 60 | 80 | ||

| Dimension (LxWxH) | cm | 45*38*25 | 60*38*25 | 90*38*25 | 90*48*29 | ||

| Excutive Standard | - | MT157-1996 | |||||

| Fire Resistance | Alcohol Blast Burner (960℃) |

The arithmetic mean of the flame combustion time | s | ≤3 | ≤3 | ≤3 | ≤3 |

| Single value of flame burning time | s | ≤10 | ≤10 | ≤10 | ≤10 | ||

| The arithmetic mean of the flameless combustion time | s | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Single value of flameless burning time | s | ≤30 | ≤30 | ≤30 | ≤30 | ||

| Alcohol burner (520℃) |

The arithmetic mean of the flame combustion time | s | ≤6 | ≤6 | ≤6 | ≤6 | |

| Single value of flame burning time | s | ≤12 | ≤12 | ≤12 | ≤12 | ||

| The arithmetic mean of the flameless combustion time | s | ≤20 | ≤20 | ≤20 | ≤20 | ||

| Single value of flameless burning time | s | ≤60 | ≤60 | ≤60 | ≤60 | ||

| Surface Resitance | Ω | ≤3 x 108 | |||||

| Water Distribution | Explosion pressure at 29m | kPa | ≤12 | ≤12 | ≤12 | ≤12 | |

| Action time to form the best mist | ms | ≤150 | ≤150 | ≤150 | ≤150 | ||

| Optimal water mist duration | ms | ≥160 | ≥160 | ≥160 | ≥160 | ||

| Optimal water mist dispersion length | m | ≥5 | ≥5 | ≥5 | ≥5 | ||

| Optimal water mist dispersion Width | m | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.5 | ||

| Optimal water mist dispersion Height | m | ≥3 | ≥3 | ≥3 | ≥3 | ||

| The above values are average for reference, allowing 10% tolerance. Customization is acceptable for all given values. | |||||||

Product Feature

◈ Used in underground mining for water containers.

◈ Isolate the spread of gas and coal dust explosions.

◈ Ensure sufficient water volume in underground mining.

◈ Stop the propagation of the shock wave caused by the coal dust explosion.

Product detail pictures:

Related Product Guide:

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Hot New Products Underground Ventilation Pipe - JULI® Explosion-Proof Water Barrier Bag – Foresight , The product will supply to all over the world, such as: Gambia, Qatar, Albania, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.